Copyright © 2025 Motivate Media Group. All rights reserved.

The North Star Pavilion explores additive manufacturing and recycling technologies in architecture

Nyxo studio unveiled The North Star pavilion at Dubai Design Week 2023

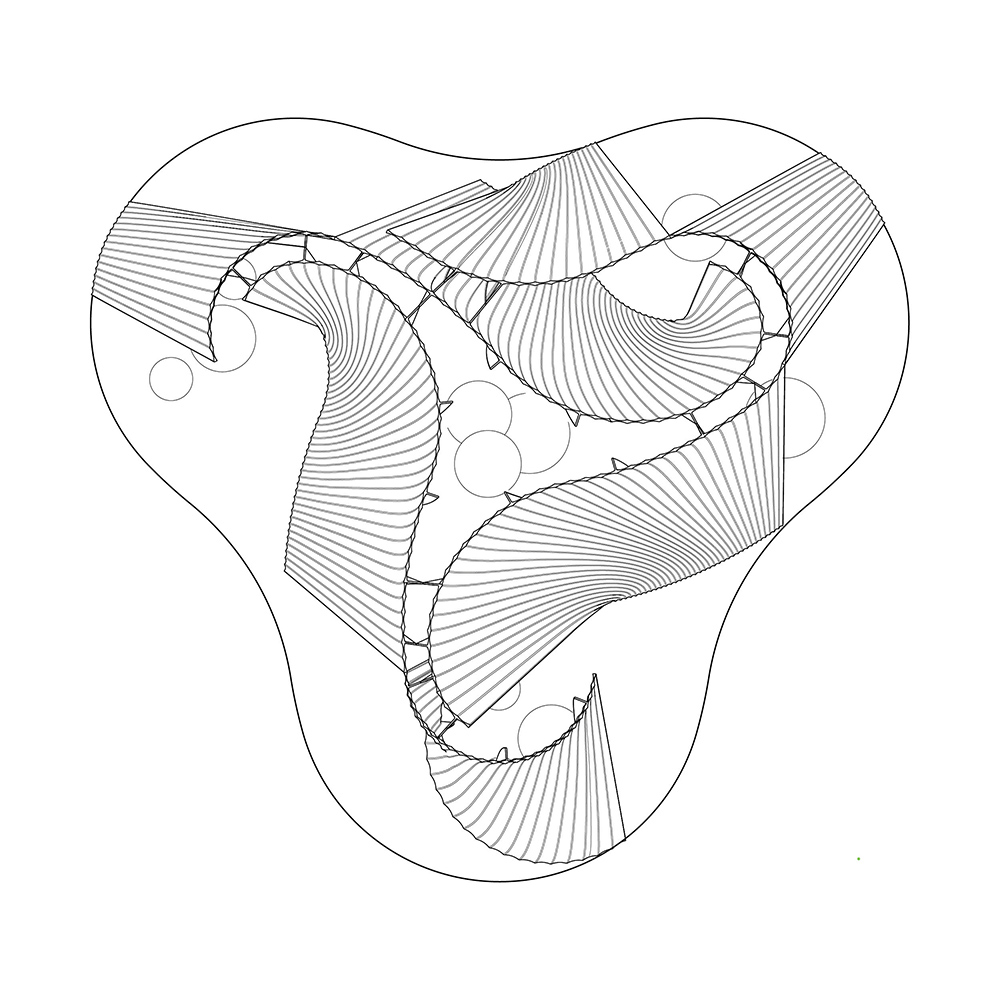

Nyxo studio recently presented The North Star pavilion, a 3D-printed structure designed as an exhibition space for startup incubator In5 to showcase the work of its companies, and to be used as a meeting space. The pavilion was showcased for the first time at Dubai Design Week 2023 and will serve future events for 2024.

The architecture

The four souls of In5 – media, technology, design and science – are represented by an infinite loop, generating four spaces that flow into each other. The loop organises the movements of a series of surfaces that meet and fold together, articulating the opening or enclosure of the spaces. The S-shaped surfaces create fluid flows between the outdoor and the indoor spaces, defining pointed arches as an homage to the ogee arches of Islamic architecture.

The surfaces are characterised by a fluted pattern that emphasises their geometry, interpolating sections of different sizes and shapes. The interior side of the walls is differentiated from the exterior by the presence of a series of structural ribs, forming an extension of the pattern in needed moments. These ribs make possible the connections between the different parts.

Additive manufacturing and material cycle

The pavilion is an exploration of the potential application of additive manufacturing (AM) and recycling technologies in architecture, showcasing the possibilities of large-scale thermoplastic printing. The pavilion is designed around the principle of repurposing and recycling. The structure is manufactured using a blend of recycled PETG with glass fibre and a UV stabiliser, ideal for long-lasting outdoor use. AM technology allows for the minimisation of waste during production, making it possible to print only the necessary material to make the panels. After its initial use, the pavilion could be recycled and, by reshaping it, it can be repurposed for different functions.

• The pavilion is made from a series of 3D-printed panels using a post-industrial recycled PETG, with 30% glass fibre and UV-stabilised (high stiffness/suitable for outdoors).

• The panels are stiffened by flutes and a series of 15cm ribs on one side of the panel.

• Each panel is 4.2 metres tall, and made from two parts, connected in the middle using naval glue and steel plates clamping the ribs from the sides.

• Each rib is connected to the platform using T-shaped steel connectors. The connectors are fixed to the wooden platform with screws.

• The panels are connected at the top. The connection is made via the ribs that meet at a series of points. The ribs are then fixed with U-shaped steel plates and screws.

• The wooden platform is a sandwich of laminated plywood and solid wood frames. The solid wood is also placed where the ribs meet the platform.

Engineering consulting:

ARUP Dubai

Simone Materazzo

Giulia Cavallari

3D printing manufacturing:

Al Seer Marine

The Latest

Studio 971 Relaunches Its Sheikh Zayed Showroom

The showroom reopens as a refined, contemporary destination celebrating Italian craftsmanship, innovation, and timeless design.

Making Space

This book reclaims the narrative of women in interior design

How Eywa’s design execution is both challenging and exceptional

Mihir Sanganee, Chief Strategy Officer and Co-Founder at Designsmith shares the journey behind shaping the interior fitout of this regenerative design project

Design Take: MEI by 4SPACE

Where heritage meets modern design.

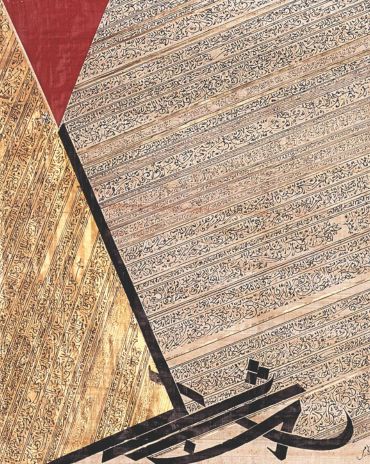

The Choreographer of Letters

Taking place at the Bassam Freiha Art Foundation until 25 January 2026, this landmark exhibition features Nja Mahdaoui, one of the most influential figures in Arab modern art

A Home Away from Home

This home, designed by Blush International at the Atlantis The Royal Residences, perfectly balances practicality and beauty

Design Take: China Tang Dubai

Heritage aesthetics redefined through scale, texture, and vision.

Dubai Design Week: A Retrospective

The identity team were actively involved in Dubai Design Week and Downtown Design, capturing collaborations and taking part in key dialogues with the industry. Here’s an overview.

Highlights of Cairo Design Week 2025

Art, architecture, and culture shaped up this year's Cairo Design Week.

A Modern Haven

Sophie Paterson Interiors brings a refined, contemporary sensibility to a family home in Oman, blending soft luxury with subtle nods to local heritage

Past Reveals Future

Maison&Objet Paris returns from 15 to 19 January 2026 under the banner of excellence and savoir-faire

Sensory Design

Designed by Wangan Studio, this avant-garde space, dedicated to care, feels like a contemporary art gallery